Hands-On Dimensional Calibration Training - 3 Days

Course Summary

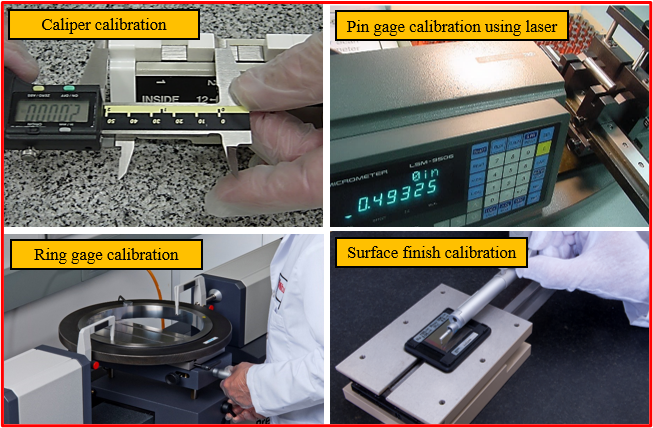

The hands-on training covers calibration of handheld dimensional measuring instruments (Outside Micrometers, Depth Micrometers, Calipers, Dial and Test Indicators, Digital Indicators, Height Gages, etc.) used every day on the shop floor and QA/QC labs. The training course also includes an overview and calibration of measurement standards used i.e., gage blocks, cylindrical pins, plugs and ring gages, spheres/balls, surface finish, etc. as these are considered foundation in dimensional metrology.

Target Audience

Target Audience

The course learning objective is geared towards students acquire necessary proficiency to independently perform calibrations, reinforce present skill level and apply learned techniques to daily activities. Hands-on approach techniques build a good foundation for individuals performing or overseeing gage calibration activities. This can simply be put in terms that:

Better Calibration = Improved Quality

Benefits

Students will get familiarized in selecting appropriate calibration methods and test points, selection of reference standards, good calibration practices, data collection, and reporting of results.

The course is a combination of 20% slideshow presentation and 80% hands-on calibration activity. The class size is kept to maximum 6 students to provide individual attention & involvement, and to minimize disruption. After a series of demonstrations, the students will focus on the hands-on activity and perform actual calibrations.

Agenda

Day 1

- Introduction and Key Concepts

- Commonly used calibration terminology, concepts and principles

- Units of measurement (UoM)

- Metrological traceability and Measurement uncertainty

- Test Accuracy Ratio (TAR) and Test Uncertainty Ratio (TUR)

- 10:1 (Inspection Rule) and 4:1 rule (Calibration Rule)

- Thermal affects and Coefficient of thermal expansion

- Significance of Expertise, Equipment and Environment in obtaining accurate measurements

- National and international standards (ASME/ANSI, ISO, Federal)

- Evaluating competency and selecting a calibration service provider

- Interpreting certificates of calibration of instruments to validate suitability

- Estimating calibration frequency of measuring instruments

- Calibration of Outside Micrometers (mechanical and digital)

- Overview, graduation & resolution, accuracy

- Define the measurand and measurement standards

- How to verify linearity, flatness, parallelism, etc.

- Cleaning and maintenance, minor adjustments

- Calibration methods and reporting of results

- Calibration of Depth Measuring Micrometers (mechanical and digital)

- Overview, graduation & resolution, accuracy

- Define the measurand and measurement standards

- How to verify linearity, base flatness, rod parallelism and straightness, etc.

- Cleaning and maintenance, minor adjustments

- Calibration methods and reporting of results

- Calibration of Length Standards

- Comparative measuring technique using surface plate, gage blocks and gage head with probe

- Absolute measuring technique using super micrometer (if available at the customer facility)

Day 2

- Calibration of Calipers (vernier, dial and digital)

- Overview, graduation & resolution, accuracy

- Define the measurand and measurement standards

- How to verify linearity, parallelism, resetting zero on dial calipers, etc.

- Cleaning and maintenance, minor adjustments

- Calibration methods and reporting of results

- Calibration of Indicators (dial and digital)

- Overview, graduation & resolution, accuracy

- Define the measurand and measurement standards

- How to verify linearity, hysteresis, cosine error, etc.

- Cleaning and maintenance, minor adjustments

- Calibration methods and reporting of results

- Calibration of Height Gages (vernier, dial and digital)

- Overview, graduation & resolution, accuracy

- Define the measurand and measurement standards

- How to verify linearity, scriber parallelism, etc.

- Cleaning and maintenance, minor adjustments

- Calibration methods and reporting of results

- Introduction to Measurement Standards (an overview)

- Gage Blocks

- Pin and plug gages

- Ring gages

- Precision Spheres/Balls

Day 3

- Calibration of Measurement Standards

- Equipment used to calibrate standards and precautions

- Gage Blocks – Cleaning and lapping techniques, wringing and stacking, measuring and evaluating the data

- Pin and plug gages – Measuring techniques and equipment, contact and non-contact measurement

- Ring gages – Measuring techniques and equipment

- Precision Spheres/Balls – Measuring techniques and equipment

- Calibration of Miscellaneous gages

- Micrometers – indicating, disc, point, blade, tri-mike, micrometer heads, etc.

- Inside measuring instruments – bore gages (2 point), hole mikes (3 point)

- Inspection type instruments – radius and angle gages, steel rulers (non-contact measurement)

- Angle measuring instruments – mechanical and digital protractors

- Surface finish instruments/Profilometers

- Precision levels

Participants will perform a mandatory Proficiency Exercise to demonstrate measurement skills using a digital micrometer (0 -1 inch/0 – 25 mm) and digital caliper (6 inch/150 mm). Participation certificate showing proficiency results is issued after the exercise is administered.

Digital Micrometer Proficiency Exercise:

The proficiency test kit includes a Digital Micrometer and four gage blocks of different sizes identified as A, B, C & D. The nominal size of each gage block is hidden and not disclosed to the participants to eliminate any bias during the exercise. The purpose of the exercise is to verify participants can measure the nominal size of the gage blocks using the digital micrometer within the instrument accuracy of ± .00005 inch/ ± 0.001 mm (± 50 µin/± 1 µm).

Digital Caliper Proficiency Exercise:

The proficiency test kit includes a Digital Caliper and a custom Caliper Checker/Step Gage. The nominal sizes of each dimension are hidden and not disclosed to the participants to eliminate any bias during the test. Each participant measures two OD dimensions and one ID dimension. The purpose of the test is to verify participants can measure the nominal size of the OD and ID using a caliper within the instrument accuracy of ± .0010 inch/±0.02 mm