Dimensional Inspection & Measurement Basics

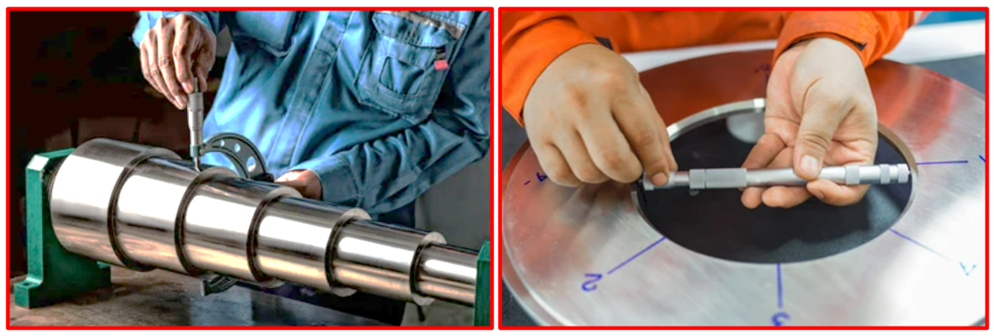

The training is an introduction to some of the most common gages & instruments used on the shop floor, inspection, and quality departments. The purpose is to provide practical instruction on the different tools available and their proper use to build workers’ skill and knowledge.

Target Audience

Course Objectives

Benefits

Basic Dimensional Inspection & Measurement Tools and Methods builds a solid foundation of skills that workers can use across a broad spectrum of applications. It forms the basis for mastering more advanced measuring tasks to ensure that you’ll get the most accurate measurements possible. With this program, workers will master the essentials of handling, applying and reading the most common gages on today’s shop floors from steel rules to micrometers, calipers, indicator and height gages.

What good is a measurement result if it has been measured incorrectly? There are many sources of measurement errors that can be easily avoided if we know how to recognize them. We focus on common measurement errors and how to avoid them!

Agenda

Introduction and Key Concepts

- Commonly used measurement terminology, concepts, and principles

- Units of measurement (UoM)

- Metrological traceability and Measurement uncertainty

- Accuracy, Precision and Bias

- Reference value, Repeatability and Reproducibility

- Measurement errors due to bias and how to reduce

- Test Accuracy Ratio (TAR) and Test Uncertainty Ratio (TUR)

- 10:1 and 4:1 rule in measurement

- Thermal effects and Coefficient of thermal expansion

- Significance of Expertise, Equipment and Environment in obtaining accurate measurements

- Evaluating competency and selecting a calibration service provider

- Interpreting certificates of calibration of instruments to validate suitability

- Estimating calibration frequency of measuring instruments

Fundamentals and Linear Tools

- Key terms and concepts

- Criteria for accurate measurements

- Rules – steel, hook, bevel protractor, basic depth gages

- Use of depth gages, inside and outside calipers, dial calipers and electronic calipers

Micrometers and Dial Indicators

- Outside, inside, vernier and electronic micrometers

- Types of dial indicators

- Dial indicating gages – calipers, depth gages

Attribute Gages (Fixed Gages)

- Snap gages

- Plug gages

- Ring gages

- Screw thread plug gages

- Thread ring gages

Surface Plate Equipment

- Surface plate equipment

- Gage blocks

- Height gages – vernier, dial, electronic

- Height master

- Surface plate accessories

Miscellaneous Equipment

- Surface Roughness Testers/Profilometers

- Shape and Profile Measurement

- Laser Designed Gaging

- Optical Comparators